Proceedings

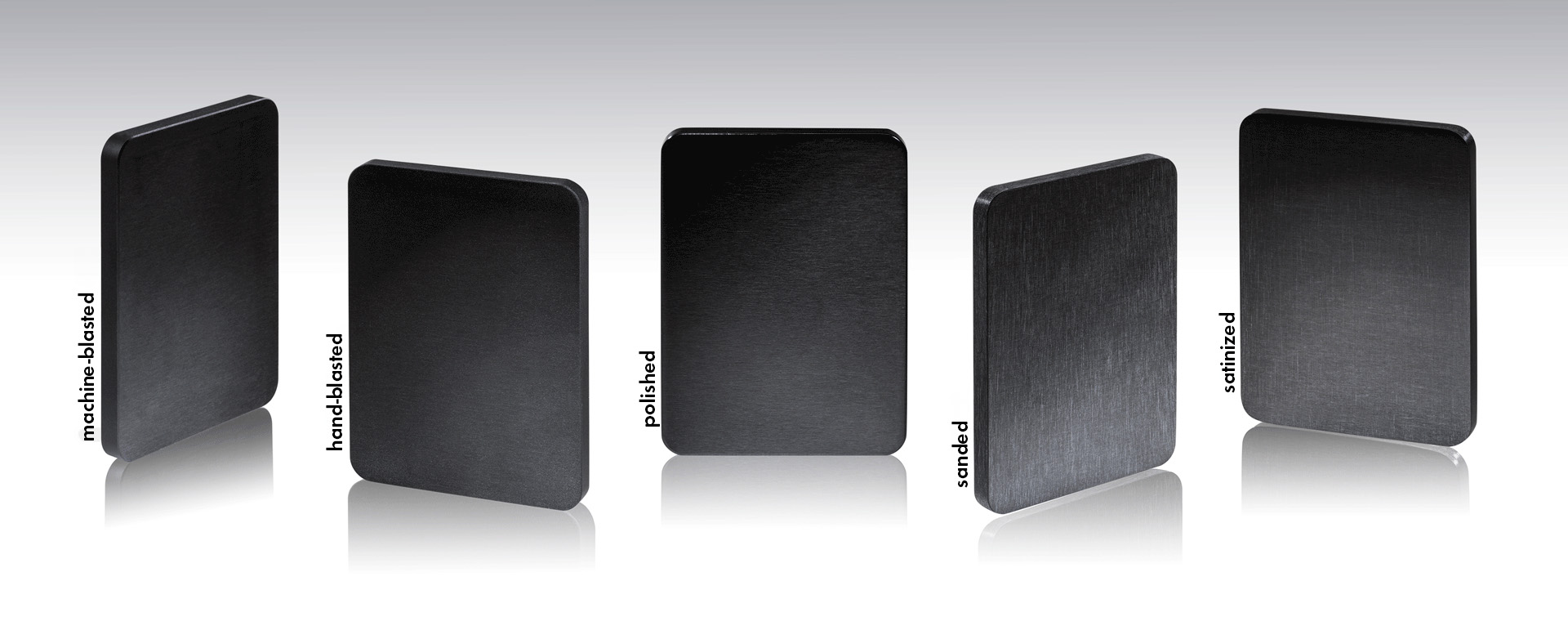

Three paths to the perfect surface

To achieve a perfect surface, Aurolia primarily utilizes three electroplating processes. With their assistance, we can positively influence many important properties of the material. Aurolia surfaces are harder, more durable, more wear-resistant, and corrosion-resistant. Our customers specify the requirements, and we create a surface layer that precisely meets their needs, from functionality to texture and appearance.

Overview of our processes

Hard anodizing

Description

In hard anodizing, aluminum materials are immersed in a special bath. By applying electrical current, targeted oxidation on the surface is provoked, giving the material extremely valuable properties. For instance, hard anodized aluminum is particularly resistant to wear, electrically insulating, and offers excellent corrosion protection. Having a component hard anodized at Aurolia means being able to determine many properties of the material itself. Hard anodized layers can range in color from light gray to gold to brown, but can also be dyed black. Additionally, to improve sliding properties, we can apply a PTFE coating, which gives the surface a lotus-like cleaning effect.

Hard facts

In our fully automated finishing plant, with a work window of 1200 x 700 x 300 mm, we can offer the following properties of hard-anodized oxide layers:

- Coating thicknesses from 25 to 100 µm

- Minimal variance in coating thickness distribution

- Excellent corrosion protection

- High wear resistance

- Hardness of approximately 500 HV (depending on the alloy)

- Food-safe

- Decorative appearance

- Excellent sliding properties due to PTFE incorporation

- Black coloring

We are happy to conduct a sampling.

FAQ Hard anodizing

Which materials are suitable for hard anodizing?

Hard anodizing is primarily suitable for aluminum and its alloys, as these materials respond particularly well to the anodizing process. Aluminum alloys with a low copper or silicon content are especially suitable, as these elements can negatively impact the quality and uniformity of the anodized layer. Alloys with higher proportions of copper or silicon tend to form a less homogeneous and less robust oxide layer, which is why they are less commonly used for hard anodizing.

In addition to aluminum, certain titanium and magnesium alloys can also be treated with hard anodizing, although this is less common. For titanium, anodizing provides a way to increase surface hardness and improve corrosion resistance, while for magnesium alloys, the focus is on protection against oxidation and mechanical wear. Nonetheless, aluminum remains the most frequently hard-anodized material, as it offers an ideal combination of lightness, strength, and anodizability.

This focus on aluminum and its specific alloys makes hard anodizing particularly valuable in industries that rely on lightweight yet robust materials, such as aerospace, automotive, and electronics. By carefully selecting suitable alloys, the hard anodizing process can be optimally tailored to the requirements of the specific application, resulting in excellent outcomes in terms of surface quality and material properties.

How does the process of hard anodizing work?

In hard anodizing, aluminum is immersed in a specially formulated acidic electrolyte solution. By applying an electric current, an extremely hard and durable oxide layer forms on the surface of the aluminum. This layer not only strengthens the surface but also significantly improves its resistance to wear and corrosion. This process, often referred to as hard coating, offers a versatile way to extend the lifespan and durability of aluminum components.

Another advantage of hard anodizing is the ability to create anodized layers in various colors, including black. Black hard anodizing is particularly popular because it combines functional durability with an attractive aesthetic component. This combination of protection and appearance makes the process ideal for applications where not only technical performance but also a high-quality look is required.

Hard anodizing, also known as aluminum hard coating, is especially useful in industries with high demands on the durability and performance of materials. These include the automotive industry, aerospace, and electronics. In these sectors, components often need to withstand extreme conditions, whether due to mechanical stress or corrosive environments. Hard anodizing enables aluminum parts to better meet these requirements while maintaining their functionality and aesthetics over long periods.

How do you maintain hard anodized surfaces?

Hard anodized surfaces are durable, but some care is still important. Clean the surface regularly with mild soapy water and a soft cloth. Avoid abrasive cleaners and hard brushes to prevent scratches. If necessary, special cleaning agents for aluminum can be used. Make sure not to use acidic cleaning agents, as they can damage the protective layer. Thoroughly dry the surface after cleaning to avoid water spots. This way, your hard anodized surface will remain attractive and functional for a long time.

Which industries use hard anodizing?

Hard anodizing is used in many industries. It is particularly popular in aerospace, as it makes aluminum components more durable. In the automotive industry, hard-anodized aluminum is also frequently used to protect parts from wear and corrosion. The electronics and medical technology sectors use hard coating on aluminum to increase the lifespan and reliability of their products. In the construction industry, hard anodizing provides durable and resilient surfaces. It is also valued in the sports and leisure industry, for example, in bicycle and outdoor equipment.

What is meant by Hard Anodized PTFE?

Hard Anodized PTFE refers to a special surface treatment for aluminum, where the material is first hard anodized (or hard coated) to create an exceptionally durable and corrosion-resistant layer. This layer is then coated with PTFE (polytetrafluoroethylene), a material known for its excellent sliding properties and the "lotus effect." This combination of hard anodized PTFE not only provides excellent protection against wear and corrosion but also gives the surface dirt-repellent properties, making it easy to clean.

What is the difference between hard anodizing and electroplating, and when is each process used?

Hard anodizing and electroplating are two different surface treatment processes, each offering specific advantages depending on the application.

Hard anodizing is an electrochemical process in which aluminum surfaces are converted into a hard, abrasion-resistant oxide layer. This is achieved by applying a voltage in an acidic electrolyte at low temperatures. The resulting layer is extremely resistant to wear and corrosion, making it ideal for applications in aerospace, the automotive industry, and mechanical engineering. Hard anodizing is particularly preferred for components that must withstand high stresses.

Electroplating, on the other hand, is a process in which a metal layer (such as nickel, chrome, or zinc) is deposited onto the component via electrolysis. This primarily serves to protect against corrosion but can also be used for decorative purposes or to improve conductivity. Electroplated surfaces are often found in electrical engineering, jewelry, or the automotive sector.

Differences and Areas of Application:

- Hard anodizing creates a chemically bonded layer, whereas electroplating deposits a metal layer onto the surface.

- Hard anodizing is exclusively suitable for aluminum, whereas electroplating can be applied to a variety of metals.

- Hard anodizing is ideal for components that are subject to high mechanical stresses or extreme environmental conditions. Electroplating is often chosen when combined protection or a decorative appearance is desired.

The choice of process depends on the specific requirements of the component. However, both processes offer distinct advantages depending on the area of application. Our team of experts is happy to assist you in finding the optimal solution for your needs.